|

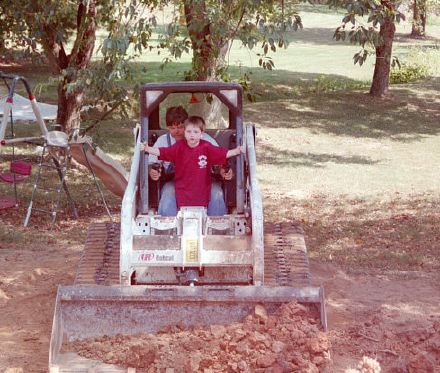

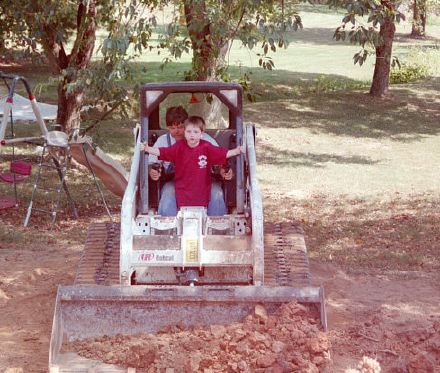

We started construction around September 1 and this shows the state of excavation after one day with a Bobcat model 864. This stuff is typical Tennessee clay, which is partly red and partly yellow. It didn't rain for a month before this excavation. When it's dry, you can dig in the red stuff, but the yellow is so hard you could lay blocks on it without a concrete foundation. The structural design requires 2000 pounds per square foot, but this clay will probably support 10 times that. There was not a rock anywhere in this hole as big as my thumb.

After we dug it out, it rained every 3rd day for 2 weeks, which slowed down the blocks.

|

|

|

Well, hurricane Isadore slowed us down a bit, with many cave-ins, but we are finally on our way.

According to by bill of lading from General Shale, this building has 41,000 lbs of blocks in it. The dead load of the steel and concrete 2nd floor won't be as heavy as the blocks are. I had to take a few blocks back and get some extras, and then I had to move some around. I figure I've picked up about 8,000 lbs of them. I don't see how people can do this kind of work.

|  |

|

One week later. The open blocks on the top are for a bond beam. I have to put steel in this and pour it full of concrete.

Note the dwindling block supply. Long objects in the middle of the building are 12 foot long lintels for over the garage door. These suckers are heavy.

|  |

|

Only 3 blocks to go in this view from my back deck.

|  |

And It's Done!

Well, the blocks at least. We had a big day on October 9 and ended it. There is some heavy hardware over those garage doors, and I am going to pour it full on concrete and make it even heavier. Split face blocks sure make for a pretty foundation in my opinion.

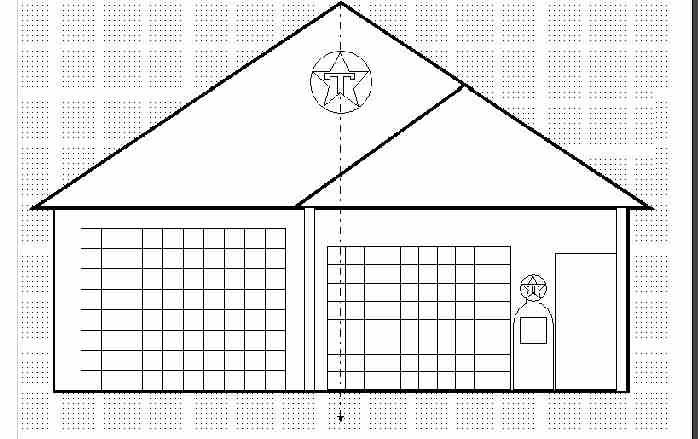

On another note, my auto lift has come in. If it hadn't been for the rain, I might actually be ready for it right now. As it is, we've lost about a month.

|  |